Alaska’s roads don’t just test your truck’s limits; they redefine them. Between spring’s frost heaves, winter’s harsh road treatments, moisture, and year-round gravel highways that never quit, your suspension and alignment face punishment most trucks will never see. If you’re noticing pulling, uneven tire wear, or strange noises from underneath, your truck is telling you something important. At 1023 Diesel & Fleet in Palmer, AK, we see the aftermath of Alaska’s brutal roads every day, and we know exactly what to look for.

In this guide, we’ll break down why Alaska’s unique conditions wreak havoc on suspension systems, reveal the warning signs you can’t afford to ignore, explain what happens when problems go unchecked, and show you how our comprehensive evaluation protects your investment and keeps you safe on the road.

Why Alaska's Roads Are Uniquely Tough on Suspension Systems

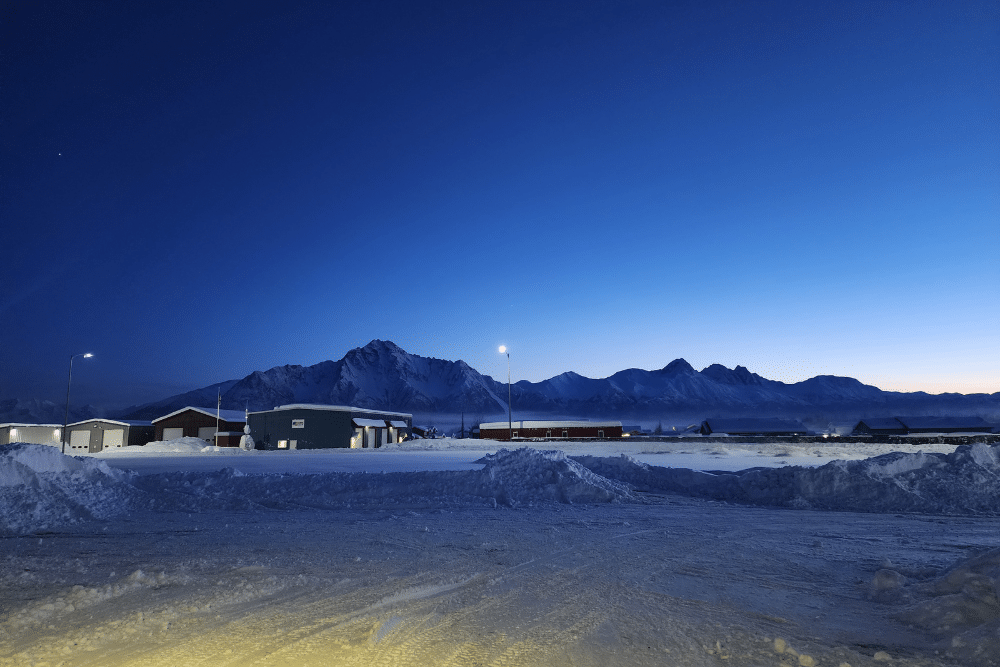

Alaska’s road conditions present challenges you won’t find in most other states. The combination of extreme temperature fluctuations, harsh winters, and remote gravel highways creates a perfect storm for suspension and alignment problems.

Freeze-Thaw Cycles Create Potholes and Frost Heaves

During Alaska’s short summers, temperatures rise quickly, causing ice beneath the pavement to melt. This creates voids under the road surface that eventually collapse, forming potholes. When winter returns, moisture in the ground freezes and expands, pushing sections of pavement upward into frost heaves. Your truck’s suspension system absorbs these impacts every time you drive, gradually wearing down components and knocking your wheel alignment out of specification.

Gravel Roads Accelerate Component Wear

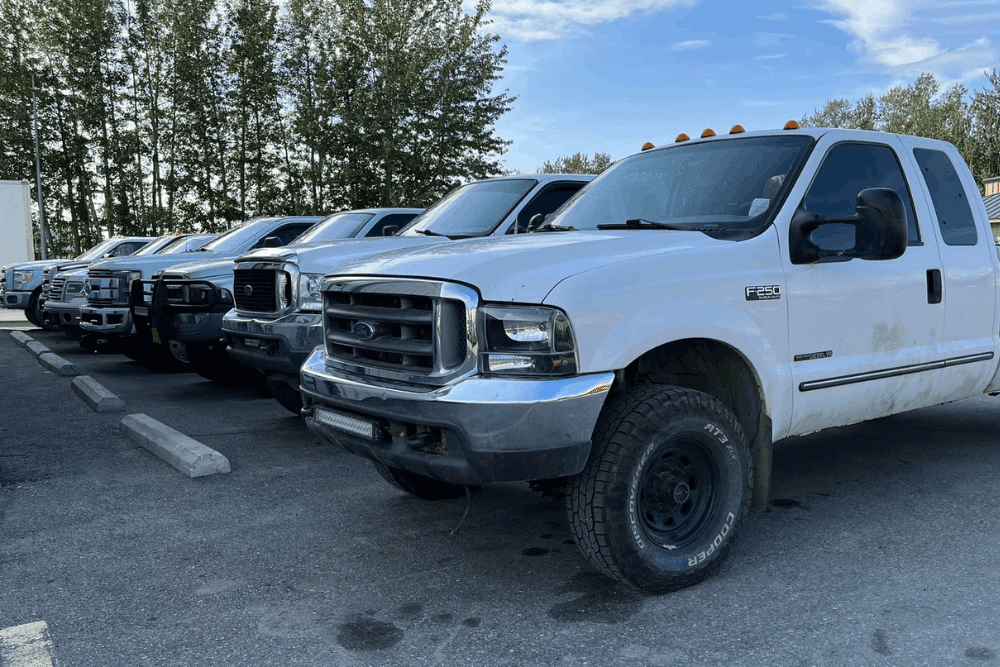

Many Alaskan highways and rural roads remain unpaved, particularly around Palmer, Wasilla, and the Matsu Valley. Gravel roads create constant vibration and impact stress on suspension components. For fleet vehicles and work trucks that travel these routes daily, the wear happens even faster. If you’re towing campers, hauling equipment, or driving with heavy loads, the stress multiplies significantly.

Winter Road Treatments and Harsh Conditions Cause Corrosion

Alaska’s Department of Transportation uses salt brine treatment and sand to combat icy roads during our long winter season. While the salt brine includes corrosion inhibitors, it still contributes to accelerated corrosion on metal suspension components. Combined with moisture from snow and slush, this treatment accelerates wear on parts that already face extreme stress in Alaska’s harsh conditions.

Warning Signs Your Truck Needs Attention

Your truck communicates problems through specific symptoms that shouldn’t be ignored. Recognizing these warning signs early prevents minor issues from becoming expensive repairs.

Watch for these common symptoms:

- Pulling to one side: Your truck drifts left or right even on straight roads

- Uneven tire wear: Tires show bald spots or wear more on the inside or outside edges

- Steering wheel vibration: Shaking or wobbling, especially at highway speeds

- Clunking or rattling noises: Strange sounds when driving over bumps or turning

- Loose steering: Excessive play in the steering wheel before the wheels respond

- Vehicle sits lower on one side: One corner appears lower when parked on level ground

If you’re experiencing handling issues, including early signs of steering instability or death wobble common in lifted trucks, these symptoms indicate your suspension and alignment need professional attention.

How Alaska's Seasons Impact Your Truck's Suspension

Understanding how each season affects your truck helps you stay ahead of problems before they become serious.

| Season | Road Conditions | Primary Suspension Threats |

|---|---|---|

| Spring Thaw (April–May) | Worst damage period with dramatic frost heaves and the largest potholes | Alignment knocked out of spec, impact damage to control arms and ball joints |

| Deep Winter (December–March) | Salt brine-treated highways, plow damage, uneven surfaces | Component brittleness from extreme cold, accelerated corrosion |

| Fall/Early Winter (September–November) | Rapid temperature drops and first freeze events | Initial frost heaves and moisture-driven corrosion |

| Summer (June–August) | Road construction, gravel detours, temporary surfaces | Construction zone damage, ideal time for pre-winter inspections |

The Real Cost of Ignoring Suspension Problems

Postponing suspension and alignment service creates consequences that extend beyond simple inconvenience.

- Premature Tire Replacement: Poor alignment dramatically shortens tire life. You might replace quality truck tires every year instead of every three years. When wheels don’t roll straight, tires scrub sideways, generating excessive heat and accelerating tread wear.

- Component Failure Cascades: A worn ball joint that could have been replaced affordably becomes a safety hazard that damages other suspension parts when it fails. What started as a simple repair becomes a complex job involving multiple components.

- Safety Risks in Winter: Compromised suspension and alignment create genuine safety risks. During Alaska’s winter months, when roads are icy and conditions are treacherous, your truck’s handling and stability can mean the difference between arriving safely and experiencing a serious accident.

Ready to get your truck inspected? Visit us at 1023 Diesel & Fleet, 530 E Steel Loop, Palmer, AK 99645, or call 907-414-8592 to schedule your appointment today.

Our Comprehensive Steering, Suspension & Alignment Evaluation

At 1023 Diesel & Fleet, our Master ASE-certified technicians and ATRA-certified specialists understand the unique demands Alaska places on your truck. We’ve invested in advanced diagnostic equipment, including our Rotary alignment rack that can handle everything from daily drivers to heavy-duty trucks like F550s. No other shop in our area has this capability.

Our Steering, Suspension & Alignment Evaluation gives you a complete picture of your truck’s front end and alignment for $189:

- Steering and suspension component inspection: We examine ball joints, tie rod ends, control arms, bushings, sway bar links, and all mounting hardware for wear, damage, and corrosion

- Alignment check and adjustment: Using precision equipment, we measure your truck’s camber, caster, and toe angles, then adjust them to manufacturer specifications

- Tire wear and pressure evaluation: We inspect tire condition, tread depth, and wear patterns

- Documentation and repair recommendations: You receive a detailed report showing what we found and what needs attention

This evaluation is ideal for daily drivers, work trucks, lifted trucks, or anyone experiencing handling issues, including early signs of steering instability or death wobble.

How Often Should You Get Your Truck Aligned in Palmer, AK

Alaska’s challenging road conditions mean your truck needs more frequent attention than vehicles in other states.

Schedule an alignment inspection:

- After hitting a significant pothole or frost heave: Impact damage can instantly knock alignment out of specification

- When installing new tires: Proper alignment maximizes tire life from the start

- Before and after winter season: Pre-winter checks ensure readiness, while post-winter inspections catch damage

- Every 6,000 to 8,000 miles for fleet vehicles: Commercial trucks on rough roads need more frequent attention

For work trucks traveling gravel highways daily or vehicles used for heavy towing, we recommend inspections every six months.

Why Choose 1023 Diesel & Fleet for Suspension and Alignment Service in Palmer

When you search for wheel alignment or suspension repair in Wasilla or Palmer, here’s what sets us apart:

- Specialized expertise in diesel and gas pickup trucks: We focus on Ford, Dodge, and Chevy light-duty trucks with the specialized knowledge these vehicles demand

- Advanced alignment equipment: Our Rotary alignment rack handles trucks up to F550 size, with a capability no other local shop can match

- Master ASE and ATRA certifications: Our technicians maintain the highest industry certifications with ongoing OEM training from Ford and Dodge

- Large parts inventory: We stock common suspension components, reducing wait times significantly

- Two-year, 24,000-mile warranty: We stand behind our work with comprehensive warranty coverage

We understand that your truck is essential for your lifestyle or livelihood. Whether you’re a business owner managing a fleet, a construction worker, or someone who enjoys Alaska’s outdoor recreation, we’re committed to keeping your vehicle safe and dependable.

FAQs About Wheel Alignment and Suspension Repair

What are the signs my truck needs an alignment?

Common signs include your truck pulling to one side while driving, uneven or rapid tire wear, steering wheel vibration, or the steering wheel sitting crooked when driving straight. These symptoms require professional inspection to prevent further damage.

How do Alaska's rough roads affect suspension?

Alaska’s freeze-thaw cycles create potholes and frost heaves that cause repeated impact stress on suspension components, while gravel roads generate constant vibration that accelerates wear. Road salt and winter conditions also cause corrosion on metal parts.

How often should I get my truck aligned?

Get alignment checks every 6,000 to 8,000 miles for work trucks or fleet vehicles, and at a minimum twice yearly for personal vehicles. Also, schedule inspections after hitting significant potholes, when installing new tires, or before and after the winter season.

What happens if I ignore suspension noise?

Ignoring suspension noise allows minor component wear to progress into complete failure, which damages other suspension parts and creates safety hazards. Simple repairs become complex jobs involving multiple components, and compromised suspension reduces your truck’s handling.

Can uneven tire wear be fixed with alignment?

Alignment service prevents further uneven tire wear by restoring proper wheel angles, but it cannot reverse wear that has already occurred. If tire wear is severe, you’ll need to replace the tires first, then get proper alignment to ensure your new tires wear evenly.

Schedule Your Suspension and Alignment Inspection in Palmer, AK Today

Alaska’s roads are tough on trucks, but regular inspections and timely repairs keep your vehicle safe and reliable. At 1023 Diesel & Fleet, we combine specialized expertise, advanced equipment, and honest service to deliver the results your truck deserves.

Don’t let Alaska’s challenging roads damage your truck or compromise your safety. Visit us at 1023 Diesel & Fleet, 530 E Steel Loop, Palmer, AK 99645, or call 907-414-8592 to book your appointment. We serve Palmer, Wasilla, Anchorage, Eagle River, and throughout the Matsu Valley. When it breaks, we fix it.